Linde Through Drive Variable Displacement Motor Repair

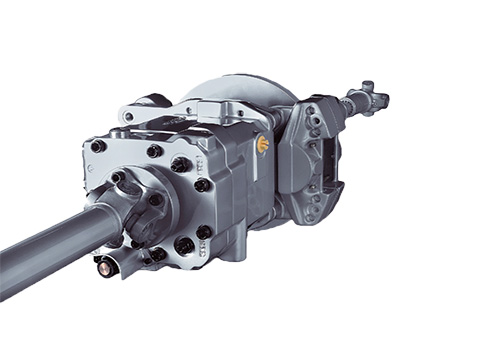

In conventional drives the torque of the hydraulic motor can be transmitted to the cardan shaft only by means of a dropbox. For further optimization of the drive train Linde Hydraulics developed the PTO Through-Drive Motor. Based on the standard hydraulic motor of the Series 02 with just one shaft end, the PTO Through-Drive Motor offers two shaft ends to transmit the torque. Hence the machine designer can conceive the hydraulic motor to fit directly and immediately into the drive train thus saving mounting space. The dropbox usually needed in a conventional propulsion drive can be saved. This reduces both noise emission and fabrication cost of the entire vehicle while overall efficiency increases.

Being customer centric, Softech Hydraulic drives it’s efforts to satisfy our trustworthy clients and we also are open to any challenges with new clients. To facilitate our clients we have also modulate the hydraulic systems in accordance to their requirements.

Displacement size from 105 -165D cc

Technical data

| HMV-02 PTO | 105 | 135 | 165 | 210 | 280 | |

|---|---|---|---|---|---|---|

| Max. displacement | cc/rev | 105 | 135.6 | 165.6 | 210 | 281.9 |

| Max. operating speed at Vmax | rpm | 3700 | 3200 | 3100 | 2700 | 2400 |

| Max. speed at Vmax* | rpm | 3800 | 3500 | 3400 | 3000 | 2700 |

| Max. operating speed at Vmin | rpm | 4100 | 3700 | 3500 | 3200 | 2900 |

| Max. speed Vmin* | rpm | 4700 | 4000 | 3900 | 3500 | 3200 |

| Nominal pressure | bar | 450 | 450 | 450 | 450 | 450 |

| Max. pressure** | bar | 500 | 500 | 500 | 500 | 500 |

| Max. housing pressure | bar | 2.5 | 2.5 | 2.5 | 2.5 | 2.5 |

| Output torque ( p=430 bar and Vmax) | Nm | 719 | 928 | 1133 | 1438 | 1929 |

| Corner power (theor.)*** | kW | 309 | 360 | 415 | 482 | 586 |

| Weight approx. (without oil) | kg | 42 | 56 | 76 | 101 | 146 |

Products/ Stock We offer.

| A10VSO1 | AR16/22 | AR37/56 | AR70/90/145 | |

| A10VSO2 | DSG01/03 | DSHG04/06/10 | BSG03/06/10 | BG03/06/10 |

| A10VSO3 | MSW01/03 | MRP01/03 | MSA01/03 | PVR-1T |